Synergy Spray Systems, we specialize in Spray Performance Analysis using advanced tools like Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA). These techniques help industries improve fluid dynamics, optimize spray coverage, and reduce prototyping costs.

What Is Spray Performance Analysis?

Spray Performance Analysis involves evaluating how well a spray system meets its intended goals. Key performance factors include:

Droplet size and distribution

Spray coverage and uniformity

Flow rate and velocity

Spray angle and pattern

Impact force and atomization quality

This ensures the system meets application goals — whether it’s cleaning, cooling, coating, or suppression.

CFD for Spray Systems: Virtual Testing Without the Downtime

Computational Fluid Dynamics (CFD) allows us to simulate:

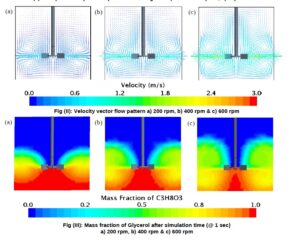

Fluid flow behavior inside pipes, nozzles, and tanks

Spray angle and droplet trajectory

Temperature and heat transfer effects

Multi-phase flows (liquid + air/mist)

By analyzing the system in a virtual 3D environment, we can predict issues like turbulence, flow separation, and mist drift before they happen.

Applications: Cooling towers, fire suppression systems, chemical dosing, cleaning systems

CFD for Spray Nozzles: Optimize Without Trial & Error

With CFD, we simulate spray nozzle behavior to optimize:

Droplet size (for misting vs coating)

Spray cone shape and angle

Atomization efficiency

Turbulence and flow path within the nozzle

This helps improve:

Fluid efficiency (less waste)

Coverage uniformity

Performance at different pressures

For example, CFD helped one client reduce overspray in a bottle washing system by 22%, cutting water usage and improving cleaning performance.

CFD FOR SPRAY SYSTEMS

cfd for agitator tank

Key Metrics We Analyze

- Droplet Size: Affects cooling/misting vs. coating/cleaning

- Spray Angle: Determines coverage width

- Flow Rate: Impacts delivery volume and force

- Spray Pattern: Full cone, flat fan, hollow cone

- Impact Force: Critical in cleaning and industrial stripping

- Atomization Quality: Ensures fine mist or even coating

Industries That Benefit from Spray Analysis

Agriculture: Improve pesticide coverage

HVAC: Optimize evaporative cooling

Manufacturing: Enhance cleaning systems

Food & Pharma: Ensure uniform coating

Fire Suppression: Verify coverage areas

Our Process

Input Requirements (system layout, fluid type, nozzle specs)

Run CFD/FEA Simulations

Analyze Spray Performance Metrics

Generate Reports with Visuals & Recommendations