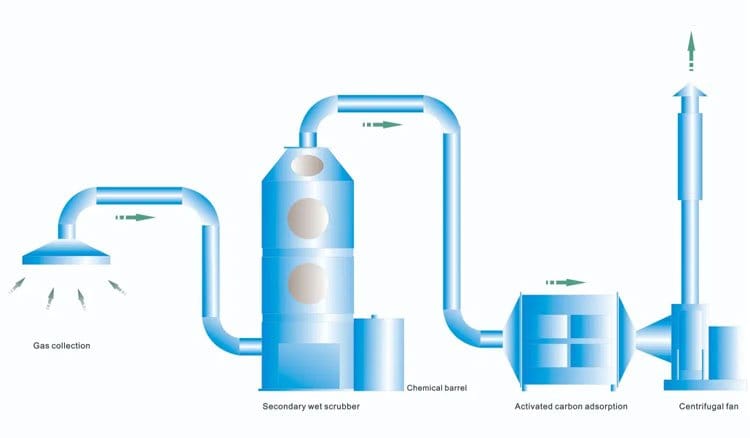

Gas scrubbing is a critical process for removing harmful gases, toxic pollutants, and particulates from industrial emissions. With increasing environmental regulations, industries must ensure that their gas treatment systems comply with strict air quality standards while maintaining efficient operations.

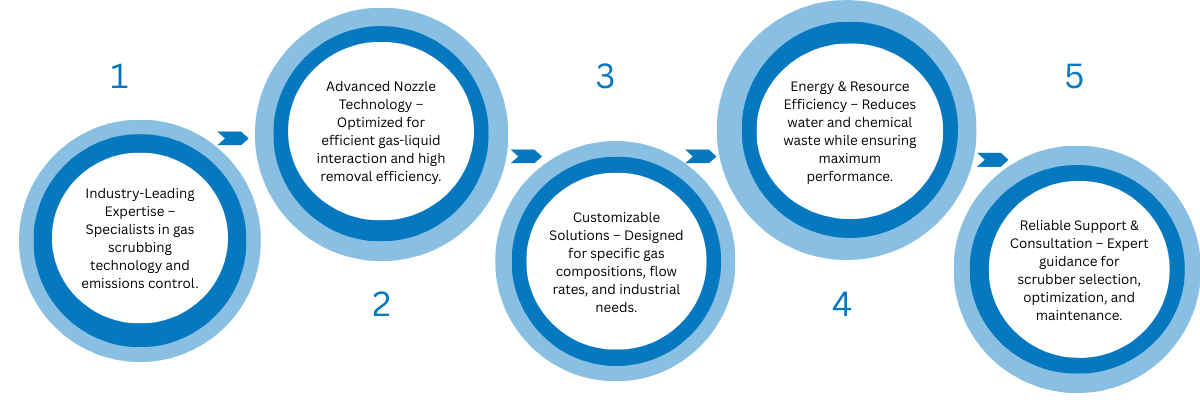

Our high-performance gas scrubbing systems and spray nozzles ensure effective pollutant removal while minimizing water and chemical consumption.

Synergy Spray, a leading manufacturer and supplier of gas scrubbers, understands the importance of maintaining air quality and regulatory compliance in various industries. Our advanced gas scrubbing solutions help prevent pollution, improve operational efficiency, and ensure a clean and safe environment. With our high-efficiency gas scrubbers and nozzles, we provide reliable solutions for air purification and environmental safety.