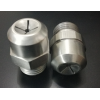

Description

Internal mixing Air Atomizing spray nozzles - Liquid and air mixed together within nozzle and dispensed through a single orifice. A change in air flow will affect the liquid flow. This makes precise metering of the liquid more difficult than with an External Mix Set-up. Internal Mix set-up are able to produce the finest atomization, but they are generally not suitable for use with liquids which have a higher viscosity.

Advantages of Siphon Nozzles:

- No Need for Pressurized Liquid Lines: Operates without requiring a pump, reducing complexity and costs.

- Ease of Installation: Simple setup with a liquid reservoir and compressed air line, making it user-friendly.

- Versatile Mounting Options: Can function even when the liquid reservoir is located below the nozzle, allowing flexibility in system design.

- Wide Range of Applications: Can spray a variety of liquids, including water, light oils, and chemicals, making it suitable for diverse industrial needs.

- Adjustable Flow Rates: By altering air pressure, the spray volume and pattern can be easily controlled.

Applications of Siphon Air Atomizers:

- Coating: Applying light oils, adhesives, or paints to surfaces in manufacturing processes.

- Cooling: Spraying water or coolants for temperature control in industrial machinery.

- Humidification: Maintaining humidity levels in controlled environments like greenhouses.

- Dust Suppression: Controlling airborne dust particles in construction or mining operations.

- Cleaning: Applying cleaning solutions in industries such as food processing or automotive manufacturing.

Reviews

There are no reviews yet.