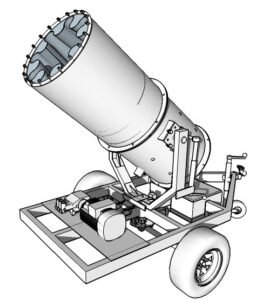

demolition water mister and dust suppression equipment

Water cannons for dust control are increasingly being used at construction, building, and demolition sites to reduce airborne dust and improve environmental conditions. This blog explores how dust suppression cannons are helping the construction industry meet environmental goals and workplace safety standards.

Why Dust Suppression is Critical in Construction and Demolition

In recent years, the need to protect green spaces, the shift toward sustainable construction practices, and advancements in demolition technologies have led to the dismantling of numerous outdated residential, commercial, and industrial structures.

However, one of the major challenges in demolition and construction activities is the release of dust particles into the air. The use of a mist cannon is an effective way to control this dust. Fine airborne dust can pose serious health risks to workers and the surrounding public, especially in densely populated or urban areas. It can also cause reduced visibility, equipment wear, and potential regulatory issues.

The Role of Fog Cannons in Dust Control

Synergy Spray Systems offers advanced dust suppression systems that address these concerns effectively. Our fog cannons or dust suppression cannons use atomized mist to capture and settle fine dust particles generated during demolition. The mist forms a damp layer over debris, preventing dust from becoming airborne again, even as heavy trucks and equipment move through the site.

This method not only improves air quality and visibility on-site but also reduces the need for additional equipment like wheel washers, which are typically required to prevent dust from spreading onto adjacent roads.

Key Benefits of Using Dust Suppression Cannons

Improved Site Safety: Reduced airborne particles enhance visibility and create a safer environment for workers.

Minimized Equipment Wear: Machinery stays cleaner and experiences less wear due to reduced dust accumulation.

Water Conservation: Atomized mist systems use significantly less water compared to traditional fire hoses or sprinklers.

Cost Savings: Lower water usage and reduced manpower lead to overall cost savings on large-scale projects.

Regulatory Compliance: Helps avoid fines and disputes with environmental or public health authorities.

Flexible & Efficient Dust Suppression

Our fog cannon systems are highly versatile. They can be:

Mounted on trailers or trucks for mobility.

Equipped with electric rotation (0° to 270°–340°) and tilt adjustments (–20° to +45°) to cover wide areas and high-rise structures.

Operated via remote control, allowing excavator operators to manage dust control without leaving their machines.

Applications of Fog Cannons

Fog Cannons are designed to control dust in:

Open mining operations

Demolition of buildings

Bulk material handling

Truck loading/unloading zones

Crushing and screening operations

Stockpile dust control

Smaller units are perfect for targeted dust suppression at specific emission points like conveyor belts, hoppers, and dumping areas. Larger units are ideal for open-area dust control, with long-throw capabilities suitable for events like blasting or large demolitions.

Tags: dust control systems for demolition | dust control systems construction | demolition dust control equipment | demolition dust suppression system