FAQs

What is a cooling tower, and how does it work?

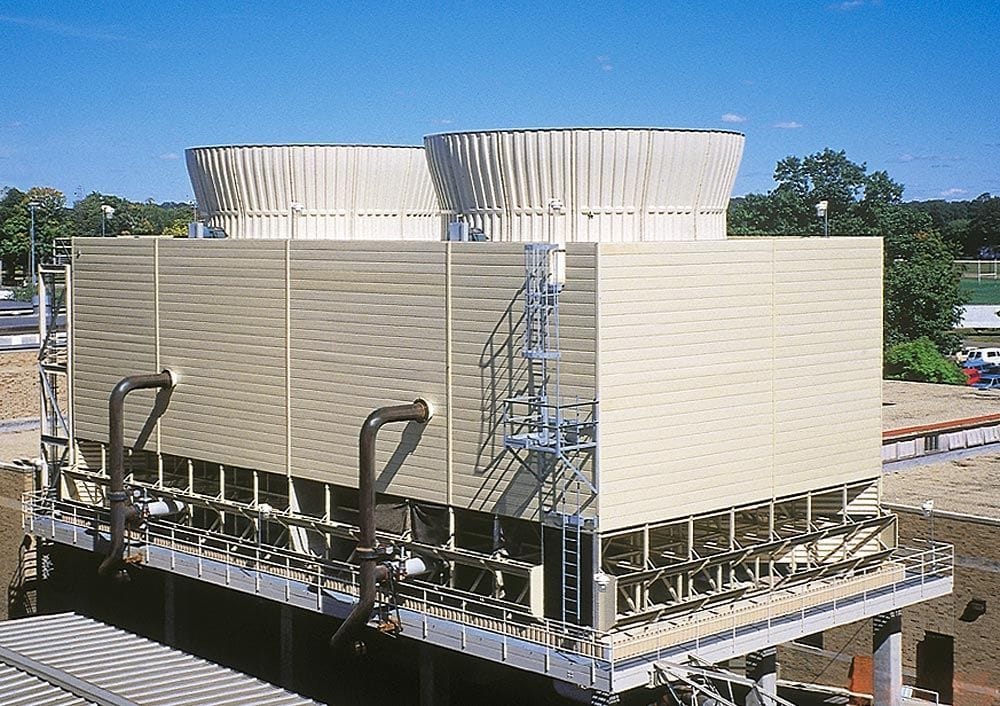

A cooling tower is a heat rejection device that removes excess heat from processes and systems by circulating water. The water is cooled by evaporation as it passes through the tower, allowing it to recirculate and maintain stable temperatures in industrial and commercial applications.

What types of cooling towers are available?

Cooling towers come in various types, including natural draft, forced draft, induced draft, counterflow, crossflow, closed-circuit, and hybrid models. Each type is suited to specific cooling needs, space constraints, and industries.

How do I choose the right cooling tower for my application?

Choosing a cooling tower depends on factors like heat load, space availability, water flow rate, energy efficiency needs, and specific application requirements. Consulting with a dealer or manufacturer can help you identify the most suitable type for your facility.

Are cooling towers energy-efficient?

Yes, modern cooling towers are designed with energy efficiency in mind, utilizing advanced fan motors, drift eliminators, and optimized fill materials to reduce water loss and minimize power consumption. Energy-saving models are available for various industrial applications.

How much maintenance does a cooling tower require?

Regular maintenance, including cleaning, water treatment, fan inspections, and fill replacement, is essential to maintain efficiency and prevent scale buildup or microbial growth. Most cooling towers require periodic maintenance schedules, which are typically every three to six months.

What is the importance of water treatment in cooling towers?

Water treatment is crucial in cooling towers to prevent scale formation, corrosion, and bacterial growth, which can lower efficiency and damage the system. Using water treatment chemicals and ensuring regular water quality monitoring will help extend the life of your cooling tower.

How can cooling towers help reduce operational costs?

Cooling towers lower operational costs by reducing energy consumption, reusing water, and preventing equipment overheating. Energy-efficient cooling towers can significantly reduce electricity and water bills in industrial and commercial settings.

What are cooling tower fills, and why are they important?

Cooling tower fills are materials that increase the surface area for water and air contact, allowing for efficient heat transfer. High-quality fills are essential for maximizing cooling performance and ensuring consistent operation.

How long do cooling towers typically last?

With proper maintenance, cooling towers can last 15 to 20 years or more. The lifespan can vary depending on usage, environmental factors, and the type of cooling tower.

Where can I find reliable cooling tower dealers in Chennai?

Chennai has several reputable cooling tower manufacturers and suppliers, such as World Cooling Towers, Perfect Cooling Towers, and Star Cooling Tower Pvt Ltd, which offer energy-efficient and customized solutions for various industrial needs.