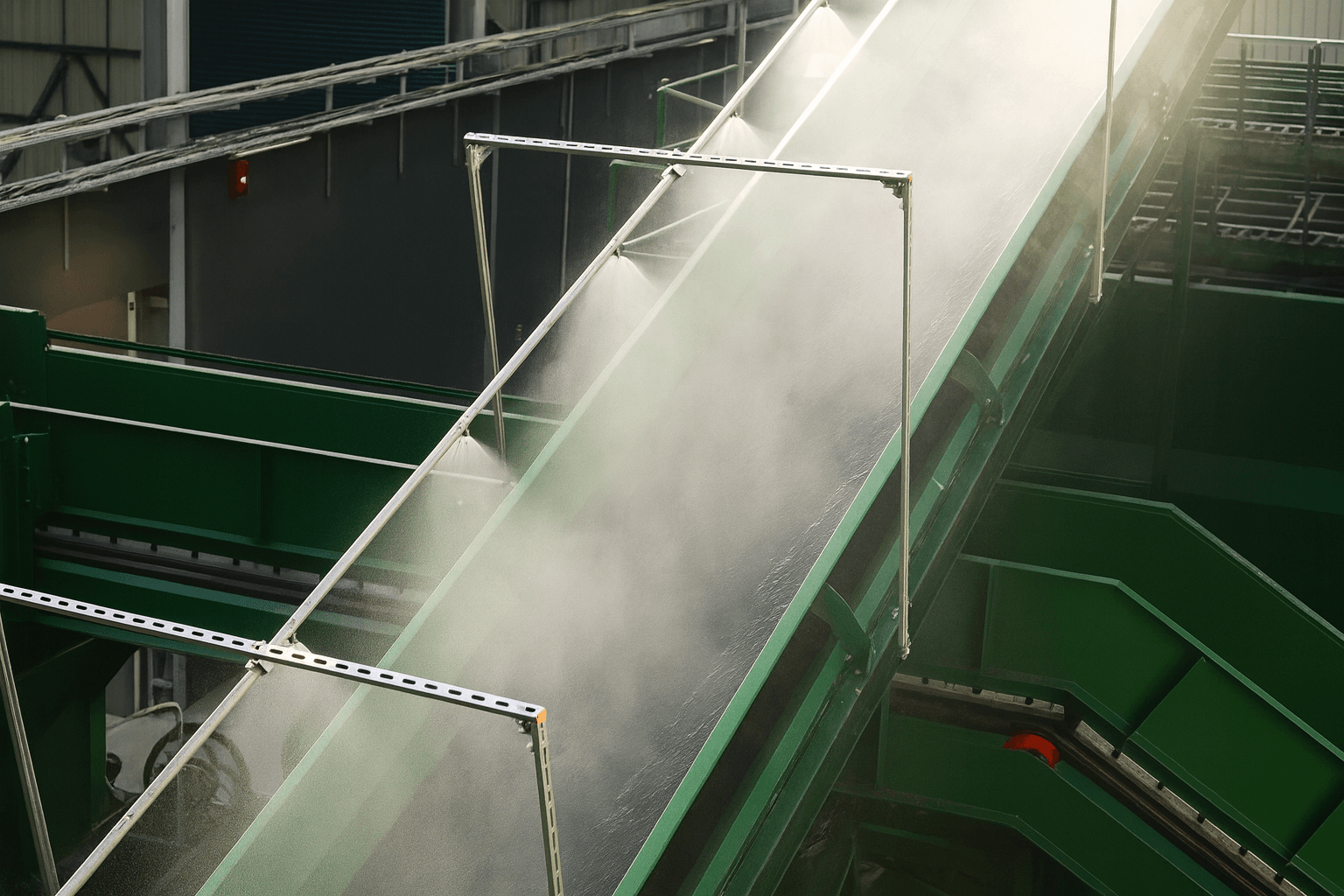

Synergy Spray Systems, we specialize in designing and delivering industrial conveyor spray solutions tailored to your operational needs. Our automated conveyor spray systems are engineered for precision, efficiency, and safety—making them essential for any industry that relies on continuous material movement.

Whether you're looking for a spray bars conveyor cleaning system or a full-scale conveyor spraying systems, our technology ensures optimal performance in sectors like food processing, pharmaceuticals, mining, automotive, and packaging.