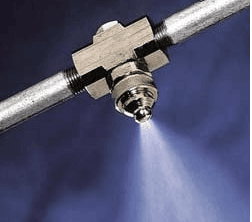

In a sprinkler system fire fighting setup, the correct spray device is critical for fast fire control and safe evacuation. Fire fighting nozzles and sprinklers fire fighting devices are engineered to deliver water, foam solution, or water mist in the right pattern and density—either to suppress flames directly or to protect equipment and escape routes through cooling and exposure protection.

Modern nozzles and sprinklers for fire fighting systems are used across industrial plants, warehouses, electrical rooms, fuel storage areas, and special hazard zones—where reliable discharge and code-based design are essential.

Fire fighting nozzles release water, foam, or mist in a controlled spray pattern to:

- Cool the fire and surrounding surfaces

- Wet combustibles to reduce ignition spread

- Shield assets from radiant heat (exposure protection)

- In water mist systems, rapid evaporation absorbs heat effectively and can reduce oxygen locally near the flame front